2023-10-31

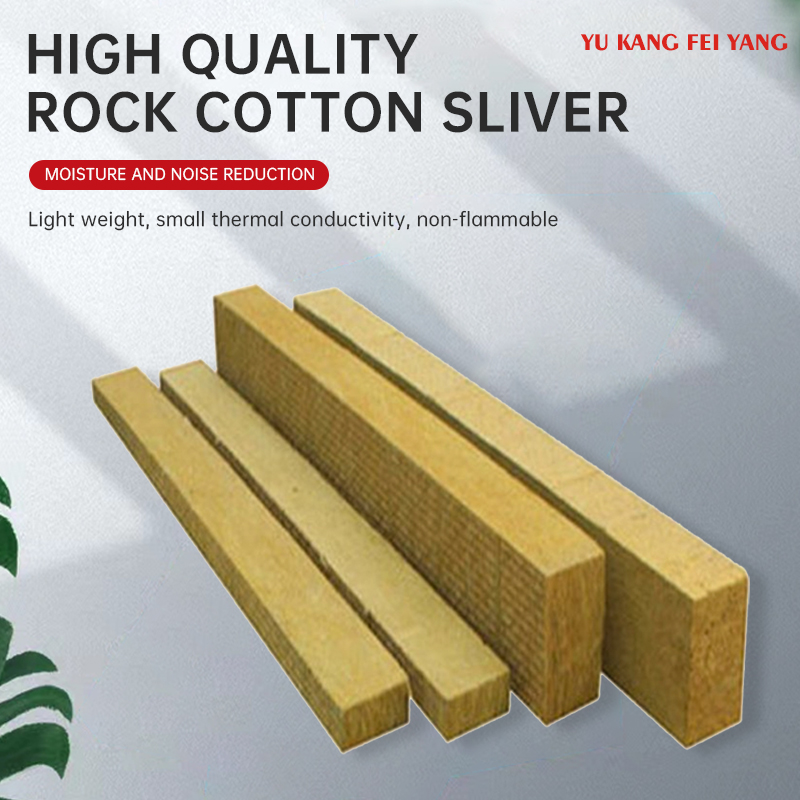

Rock wool strip is made from natural basalt as the main raw material. After high-temperature melting, it is made into artificial inorganic fibers by high-speed centrifugal equipment. At the same time, special binders and dustproof oil are added, and then heated and solidified to produce various specifications and requirements of rock wool insulation products.

Rock wool strip is made from natural basalt as the main raw material. After high-temperature melting, it is made into artificial inorganic fibers by high-speed centrifugal equipment. At the same time, special binders and dustproof oil are added, and then heated and solidified to produce various specifications and requirements of rock wool insulation products. Rock wool strip products are suitable for thermal insulation, sound insulation, and other applications in industrial equipment, buildings, and ships.

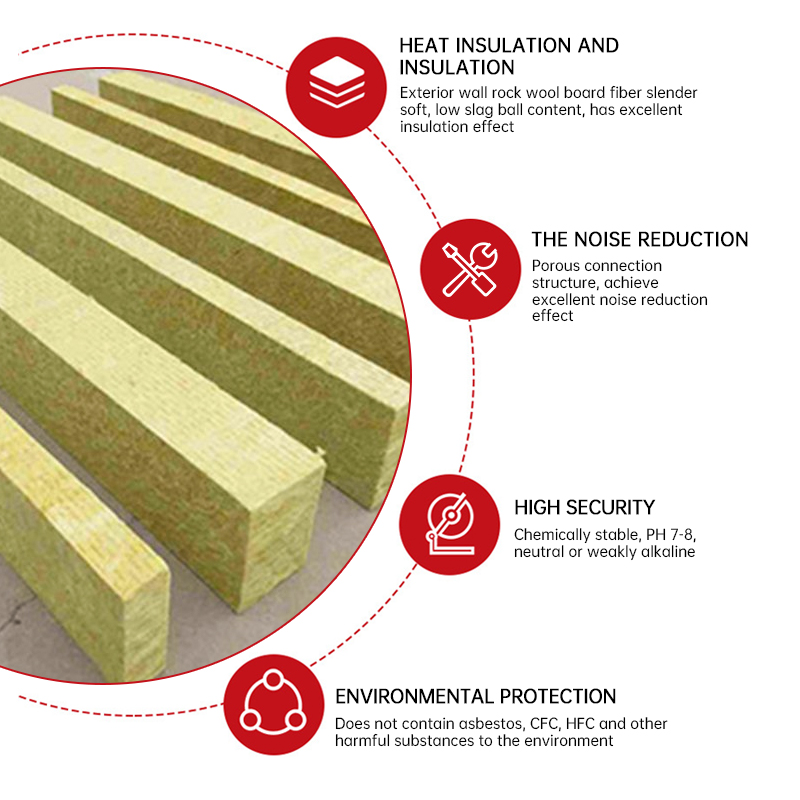

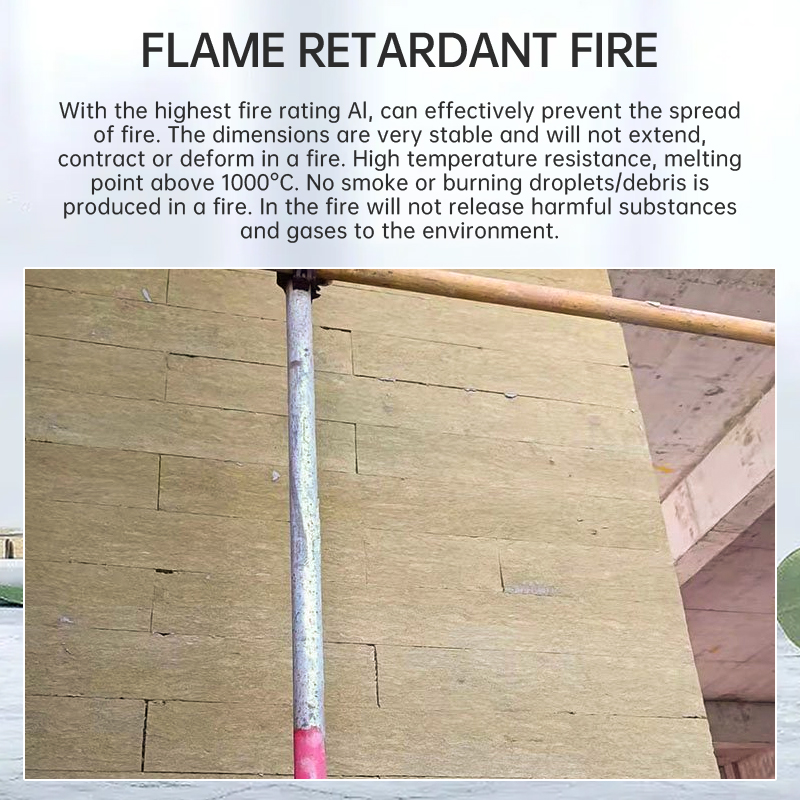

Sound absorption/soundproofing: The open structure of rock wool strips provides excellent sound absorption/soundproofing performance. Fire resistance: This product is tested as non combustible according to astm e-136 standard.

Compressive strength: Rock wool strips are processed from compression plates, and the fibers are upright in the assembly line process, so they can bear high loads.5%: Pressure resistance>25kpa; 10%: Pressure resistance>40kpa.

Moisture resistance: Rock wool strips are waterproof and have good ability to release water vapor pressure to the roof structure.

Chengdu yukang feiyang thermal insulation materials co., ltd. Is a modern enterprise producing energy-saving and environment-friendly building materials such as thermal insulation materials, fire-resistant and fireproof materials, sound absorption and noise elimination materials.

The main products include xps extruded board, glass wool products, fire and thermal insulation rock wool products, eps polystyrene board, a-grade polyphenylene board (permeable, granular), aluminum silicate ceramic products, rubber sponge products, polyurethane, high pressure polyethylene (pef), asbestos free microporous calcium silicate, foam glass, foam cement insulation board, vitrified beads and inorganic vitrified beads, expanded perlite, perlite board, etc.

The company integrates scientific and technological development, production, manufacturing and sales. At the same time, in order to transform the first-class technology into first-class products, the company implements scientific management on all equipment and production technologies, and tracks and monitors the quality and technology of production processes throughout the city.

The company adheres to the business tenet of "honesty". With the increasing demand of domestic and foreign markets, we will further expand the production and sales scale on the premise of improving quality and increasing varieties. No matter now or in the future, we will continue to serve our customers, and we sincerely welcome new and old customers to visit and guide us.

Fu Honghui

609816814@qq.com

Changsha’s Tianxin District Celebrates Lantern Festival with Four-City Historic Tower Light Linkage

Xun County, C China's Henan: Young Artisans in "Hometown of Stone Carving" Bring Millennium-Old Craft to Life

Inside MWC 2026: See How China Mobile Leads the Tech Innovation Wave

China Eastern Airlines Announces Comprehensive Upgrade to International Route Network in 2026

SOUEAST S08 DM Pre-sale Opens in the UAE:"Motorsuite" Redefines Quality Travel

iCAUR Makes Strategic Entry into the Middle East: Announcing V27's Global Launch in UAE

©copyright 2009-2020 Singapore Info Map