2022-11-15

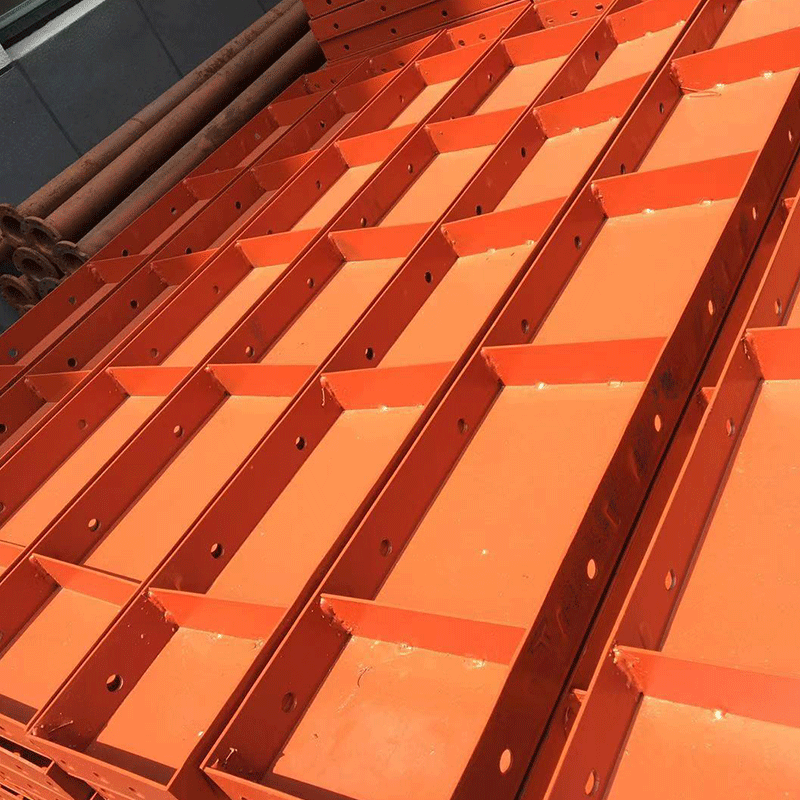

Cylindrical formwork is a new type of formwork material belonging to the field of construction engineering technology, which is composed of three parts: panel, support structure and connecting parts, of which the panel is a load-bearing plate in direct contact with the newly poured concrete; The support structure is a temporary structure that supports the panel, concrete and construction load, which can make the cylindrical formwork structure firmly combined without damage or deformation, and the connecting part is the connecting part that connects the panel and the support structure into one. This formwork is a stereotyped formwork made according to a certain modulus, using the flexibility of wood plywood, setting different arcs under high temperature and high pressure to reach different diameters, so that it can be used to form curved buildings and complete the pouring of concrete.

Advantages:

1. The product has few seams, high flatness, tight longitudinal seam contact, and no need to worry about running pulp.

2. Its thermal insulation characteristics are also relatively reliable: according to statistics, its unique air permeability makes the overall actual effect of concrete poured above all, so the concrete surface is smooth and uniform after concrete pouring, and the color is consistent.

3. No need for complex outer mold support system: in fact, the cylindrical steel formwork is reinforced every 300mm at the connection with the main and secondary openings, and the outer side is reinforced by a steel chain structure, and the vertical positioning is carried out according to the horizontal and longitudinal ribs of the seamless steel pipe, and the vertical practical effect is very good.

4. Easy forming, easy disassembly and assembly, high efficiency: the template is made and processed according to the different requirements of each layer of the cylinder, and can be cut with laser at will, which further improves the work efficiency.

5. Easy installation: The installation of the product is very convenient, two people can install a few meters high mold, greatly reducing the labor efficiency of the actual operator.

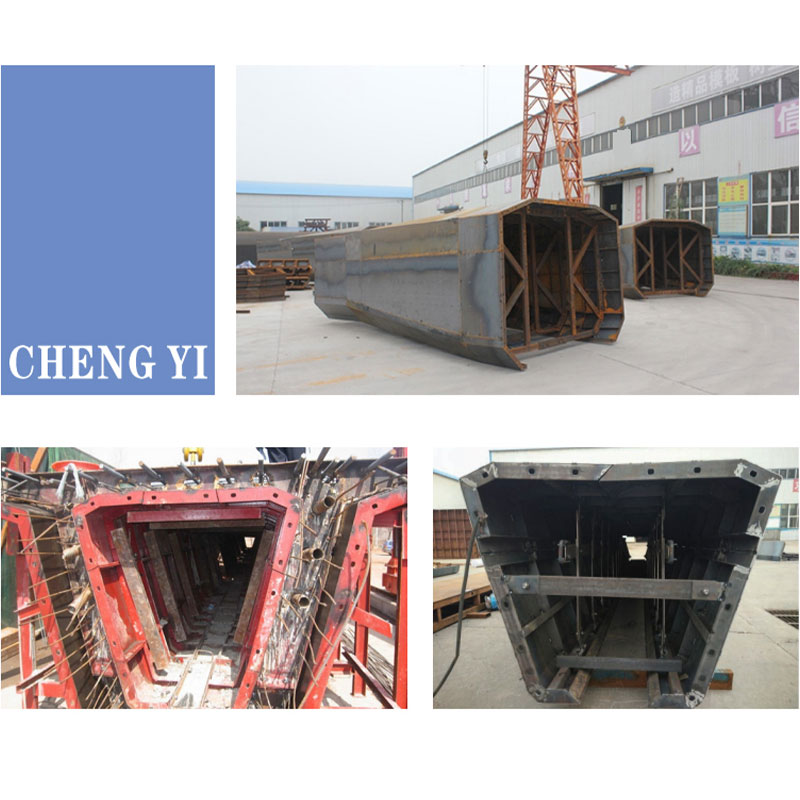

Founded in 2016, the company is a manufacturing enterprise focusing on the research, development, production and sales of steel formwork products and steel formwork products. The company has long been engaged in the research and development, design, sales and manufacturing business of dissimilar steel formwork used in highway, railroad, large power station, municipal railroad, light rail and other projects.

The company mainly produces the following products: bridge pier column formwork, tie beam formwork, cover beam formwork, T-beam formwork, crash wall formwork, high speed rail shelter formwork, construction hanging basket, tunnel dolly, cylindrical formwork and flat combination steel formwork.

Cheng Yuan

673606244@qq.com

metk452@gmail.com

SOUEAST S08 DM Pre-sale Opens in the UAE:"Motorsuite" Redefines Quality Travel

iCAUR Makes Strategic Entry into the Middle East: Announcing V27's Global Launch in UAE

iCAUR Makes Strategic Entry into the Middle East: Announcing V27's Global Launch in UAE

MEXC Ranks No. 1 in XAUT Perpetual Volume Globally, Demonstrating Strong Liquidity and User Activity

ZHAO Shanrui's Sales Symbiosis Practice

2026 CIIC H-Inno Pitch Competition Convenes at Harvard Business School, Advancing AI-Driven Global Innovation

©copyright 2009-2020 Singapore Info Map